Boitsebiso:alloy ea bongaka ea titanium

Tlhaloso ea lihlahisoa

| Ntho No. | Tlhaloso | |

| 11.07.0115.004124 | 1.5 * 4mm | E senang anodized |

| 11.07.0115.005124 | 1.5 * 5 limilimithara | |

| 11.07.0115.006124 | 1.5 * 6mm | |

| Ntho No. | Tlhaloso | |

| 11.07.0115.004114 | 1.5 * 4mm | Anodized |

| 11.07.0115.005114 | 1.5 * 5 limilimithara | |

| 11.07.0115.006114 | 1.5 * 6mm | |

Likaroloana:

•alloy ea titanium e tsoang kantle ho naha ho fihlela boima bo botle ka ho fetesisa le ho fetoha habonolo

•Switzerland TONRNOS CNC othomathiki oa ho itšeha lathe

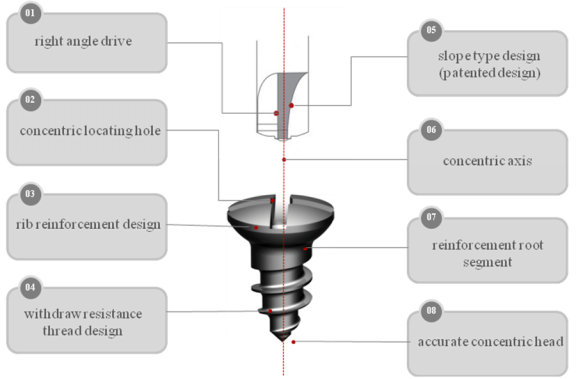

•ts'ebetso e ikhethang ea oxidation, ho ntlafatsa ho thatafala ha sefahleho sa screw le ho hanyetsa ho roala

Sesebelisoa se tsamaellanang:

sefapano hlooho screw driver: SW0.5 * 2.8 * 75mm

mokgoa o otlolohileng o potlakileng wa ho kopanya

Lipoleiti tsa boemo bo tlase ba boemo bo tlase bo chamfered le profil e pharaletseng ha li fane ka matla.E fumaneha ka bolelele bo ikhethileng haholoanyane.

Melemo ea li-screws tsa titanium alloy:

1. Matla a phahameng.Boima ba titanium ke 4.51g/cm³, e phahame ho feta ea aluminium 'me e tlase ho feta ea tšepe, koporo le nickel, empa matla a phahame haholo ho feta a lirafshoa tse ling.Screw e entsoeng ka titanium alloy e bobebe ebile e matla.

2. Ho hanyetsa kutu e ntle, titanium le alloy ea titanium mecheng e mengata ea litaba e tsitsitse haholo, li-screws tsa alloy tsa titanium li ka sebelisoa libakeng tse sa tšoaneng tse senyang habonolo.

3. Ho hanyetsa mocheso o motle le ho hanyetsa mocheso o tlaase. Li-screws tsa alloy tsa Titanium li ka sebetsa mocheso ho fihlela ho 600 ° C le ho tlosa 250 ° C, 'me li ka boloka sebōpeho sa tsona ntle le ho fetoha.

4. Non-magnetic, non-toxic.Titanium ke tšepe e se nang makenete 'me e ke ke ea hoketsoa libakeng tse phahameng haholo tsa makenete.Eseng feela e seng chefo, 'me e na le tumellano e ntle le' mele oa motho.

5. Ts'ebetso e matla ea ho thibela metsi.Ha e bapisoa le tšepe le koporo, titanium e na le nako e telele ka ho fetisisa ea ho thothomela ka mor'a ho sisinyeha ha mochine le ho sisinyeha ha motlakase. Ts'ebetso ena e ka sebelisoa e le lifereko tsa tokiso, likaroloana tsa vibration tsa li-grinder tsa bongaka tsa ultrasonic le lifilimi tsa vibration tsa libuela-hōle tse tsoetseng pele. .

Moralo oa khoele bakeng sa ho qala screw ka potlako le torque e tlase ea ho kenya.Khetho e pharalletseng ea lipoleiti le mesh, ho kenyeletsoa mastoid le meshes ea nakoana, le likoahelo tsa lesoba la li-shunts.

Ha sekurufu se tiea, ho molemo hakae?

Hangata li-screw li sebelisoa ho buuoa ka masapo ho hatella sebaka sa ho robeha, ho lokisa poleiti ho lesapo, le ho lokisa lesapo ho foreimi ea ka hare kapa ea ka ntle. ngaka e buoang.

Leha ho le joalo, ha matla a torque a ntse a eketseha, screw e fumana matla a maholo a torque (Tmax), ka nako eo matla a ho tšoara ha screw holim'a lesapo a fokotseha 'me a ntšoa sebaka se senyenyane.Pull-out force (POS) ke tsitsipano. ho sotha sekurufu lesapong.Hangata e sebelisoa e le parameter ho lekanya matla a ho tšoara screw. Hona joale, kamano pakeng tsa torque e kholo le matla a ho hula e ntse e sa tsejoe.

Hangata, lingaka tse buoang tsa masapo li kenya screw ka hoo e ka bang 86% Tmax. Leha ho le joalo, Cleek et al.o fumane hore 70% Tmax ho kenngoa ha screw holim'a tibia ea linku ho ka finyella boholo ba POS, e leng se bontšang hore matla a feteletseng a torsion a ka sebelisoa kliniki, e leng ho ka fokotsang botsitso ba ho lokisa.

Phuputso ea morao-rao ea li-humerus ka har'a batho ka Tankard et al.e fumane hore boholo ba POS bo fumanoe ho 50% Tmax. Mabaka a ka sehloohong a phapang pakeng tsa liphello tse ka holimo e ka 'na ea e-ba ho se lumellane ha mehlala e sebelisoang le litekanyetso tse fapaneng tsa tekanyo.

Ka hona, Kyle M. Rose et al.ho tsoa United States ho ile ha lekanya kamano pakeng tsa Tmax e fapaneng le POS ka li-screws tse kentsoeng ka har'a tibia ea cadaver ea batho, 'me ea boela ea hlahloba kamano pakeng tsa Tmax le BMD le cortical bone thickness.Pampiri e sa tsoa hatisoa ho Techniques in Orthopedics. boholo le POS e tšoanang e ka fumanoa ho 70% le 90% Tmax ka screw torque, 'me POS ea 90% Tmax screw torque e kholo haholo ho feta ea 100% Tmax.Ho ne ho se na phapang pakeng tsa BMD le botenya ba cortical pakeng tsa lihlopha tsa tibia, 'me ho ne ho se na kamano pakeng tsa Tmax le tse peli tse ka holimo. ka tlase ho Tmax.Le hoja 70% le 90% Tmax e ka finyella POS e tšoanang, ho ntse ho e-na le melemo e meng ea ho tiisa sekoti, empa torque ha ea lokela ho feta 90%, ho seng joalo phello ea ho lokisa e tla ameha.

Mohloli: Kamano Pakeng Tsa Torque e Insertional le Pullout Strength of Surgical Screws.Techniques in Orthopaedics: June 2016 - Volume 31 - Issue 2 - p 137–139.

-

ho notlela maxillofacial micro double Y plate

-

ho notlela maxillofacial micro Y plate

-

orthognathic 0.6 L poleiti 4 masoba

-

orthognathic 1.0 sagittal petsoha e tsitsitseng 6 masoba leq...

-

maxillofacial trauma micro double Y plate

-

orthognathic 1.0 L palte 6 masoba